As automation and digitalization continue to shape the landscape of modern manufacturing, the need for precision, reliability, and safety in machine components becomes more critical than ever. Among the many technologies that keep production systems running smoothly, brakes play a fundamental role in ensuring operational safety, controlled motion, and energy efficiency.

One name that stands out in this field is the German manufacturer Stromag. Known for its wide range of clutches and brakes for electromechanical systems, Stromag brakes are essential in various sectors including machine tools, textile manufacturing, the paper industry, and packaging technology.

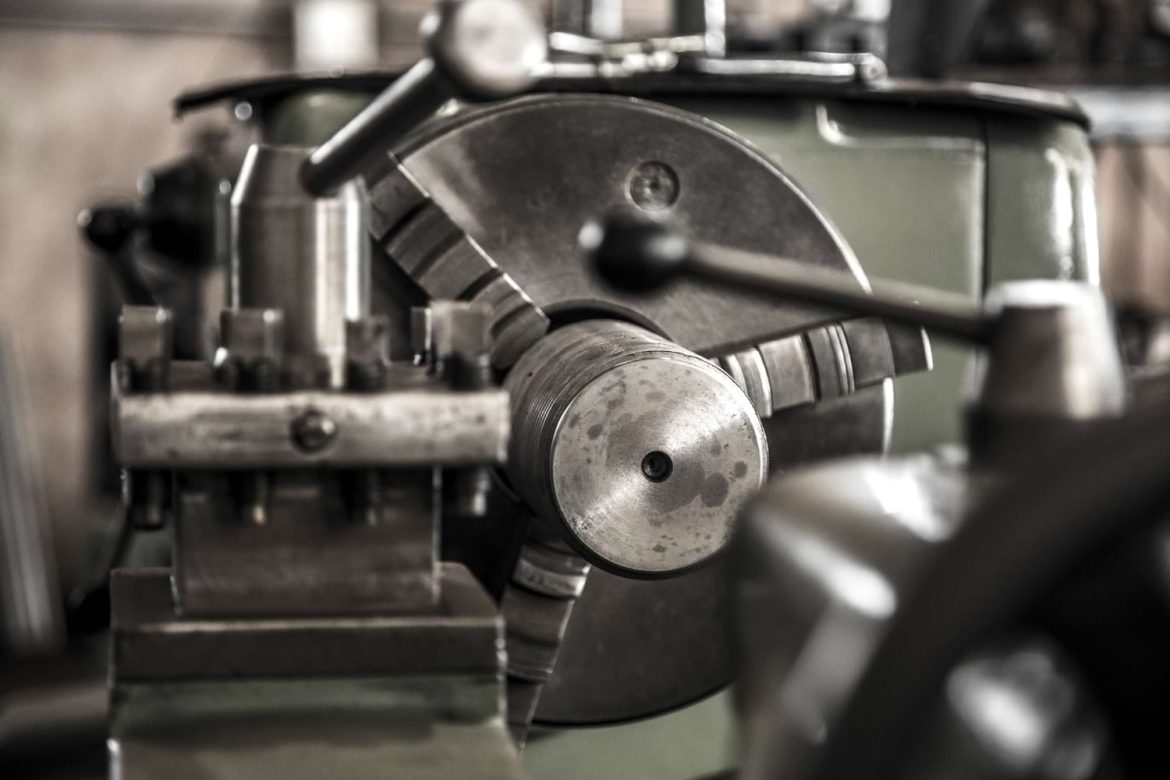

Stromag has built its reputation over decades by designing and producing state-of-the-art brakes and clutches. The company’s products are specifically developed to meet the rigorous demands of electric machines, including CNC milling machines, gearboxes, and industrial wrapping systems. Whether it’s about withstanding high loads, enduring long operating hours, or enabling precise movement, Stromag brakes are engineered to deliver peak performance under all conditions.

Technological Diversity and Customization of Stromag Brakes

One of the standout features of Stromag brakes is their diverse portfolio of brake systems, designed to accommodate a wide array of applications. Stromag offers both spring-applied safety brakes and electrically released service brakes. These systems are not only versatile in terms of application but are also highly customizable to fit into existing machinery setups. For example, the NFF series of spring-applied brakes automatically engage when power is cut, ensuring a secure hold — a critical feature for applications where safety is paramount.

In textile machinery, quick and gentle braking is essential to avoid damaging delicate materials, while in paper production, brakes must be built for continuous, long-term use with minimal downtime. Stromag brakes cater to these different needs with precision. Their robust design ensures a long service life even in the most demanding environments, reducing maintenance costs and operational interruptions. Another strength lies in the adaptability of their products; they can be seamlessly integrated into older systems or cutting-edge automation setups alike.

Energy Efficiency and Industry 4.0 Integration

In an era where energy efficiency and environmental impact are critical concerns, Stromag brakes are designed not only for mechanical excellence but also for energy-conscious operation. Many of their modern brake models incorporate features that enable energy recovery, reduced power consumption, and real-time performance monitoring. Equipped with advanced sensors, these brakes offer predictive maintenance capabilities, allowing operators to avoid costly failures and schedule service intervals more efficiently.

Take, for instance, their use in CNC machine tools: stopping and holding must happen within milliseconds without causing vibrations that could impair the machining process. Stromag brakes achieve this through finely tuned dynamics and control algorithms that guarantee smooth, reliable operation. In conjunction with frequency inverters or servo drives, they offer smart control interfaces for advanced system integration, making them ideal for applications aligned with Industry 4.0 principles.

This smart connectivity not only enhances performance but also contributes to a significant reduction in energy loss. By allowing machines to operate closer to their optimal performance ranges, Stromag brakes help manufacturers achieve both their productivity and sustainability goals. Their low-maintenance design and high durability also make them a cost-effective choice in the long run.

A Reliable Solution for the Demands of Modern Industry

Stromag brakes exemplify the combination of German engineering excellence, innovation, and practical reliability. Serving a wide range of industries — from textiles and paper to heavy-duty gearboxes and packaging equipment — they provide vital functionality for electromechanical systems. These brakes are not just safety components; they are efficiency boosters, offering enhanced control, energy savings, and maintenance-friendly operation.

For businesses aiming to optimize their production systems with high-quality, scalable, and future-proof components, Stromag brakes are an outstanding choice. Their modular architecture, broad variety of configurations, and application-specific customization options make them a trusted partner in the machinery of tomorrow. In a time when industrial success increasingly depends on smart, safe, and sustainable solutions, Stromag brakes deliver the precision and performance that the modern world demands.

Author Profile

Latest entries

Home & GardenSeptember 25, 2025Ventilazione moderna: efficienza e design negli edifici

Home & GardenSeptember 25, 2025Ventilazione moderna: efficienza e design negli edifici TechnologyJune 22, 2025Modern Air Quality Monitoring Technologies

TechnologyJune 22, 2025Modern Air Quality Monitoring Technologies Health & BeautyMay 28, 2025Trakční klece jako součást moderní rehabilitační terapie

Health & BeautyMay 28, 2025Trakční klece jako součást moderní rehabilitační terapie TechnologyApril 20, 2025Why High-Ticket Businesses Need a Reliable Merchant Account for Stripe

TechnologyApril 20, 2025Why High-Ticket Businesses Need a Reliable Merchant Account for Stripe